HANOMAG LOHNHÄRTEREI GRUPPE

Kompetent in der Wärmebehandlung von Stahl- und Aluminiumbauteilen, sowie der mechanischen Bearbeitung vom Rohteil bis zum einbaufähigen Fertigteil

Die Hanomag Lohnhärterei Gruppe zählt seit über 30 Jahren zu den führenden Lohnhärtereien in Deutschland.

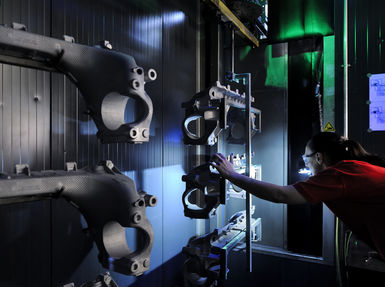

Unser Dienstleistungsangebot umfasst das gesamte Verfahrensspektrum im Bereich der Wärmebehandlung und wird ergänzt durch viele vor- und nachgelagerte Prozesse sowie Mess- und Prüfdienstleistungen.

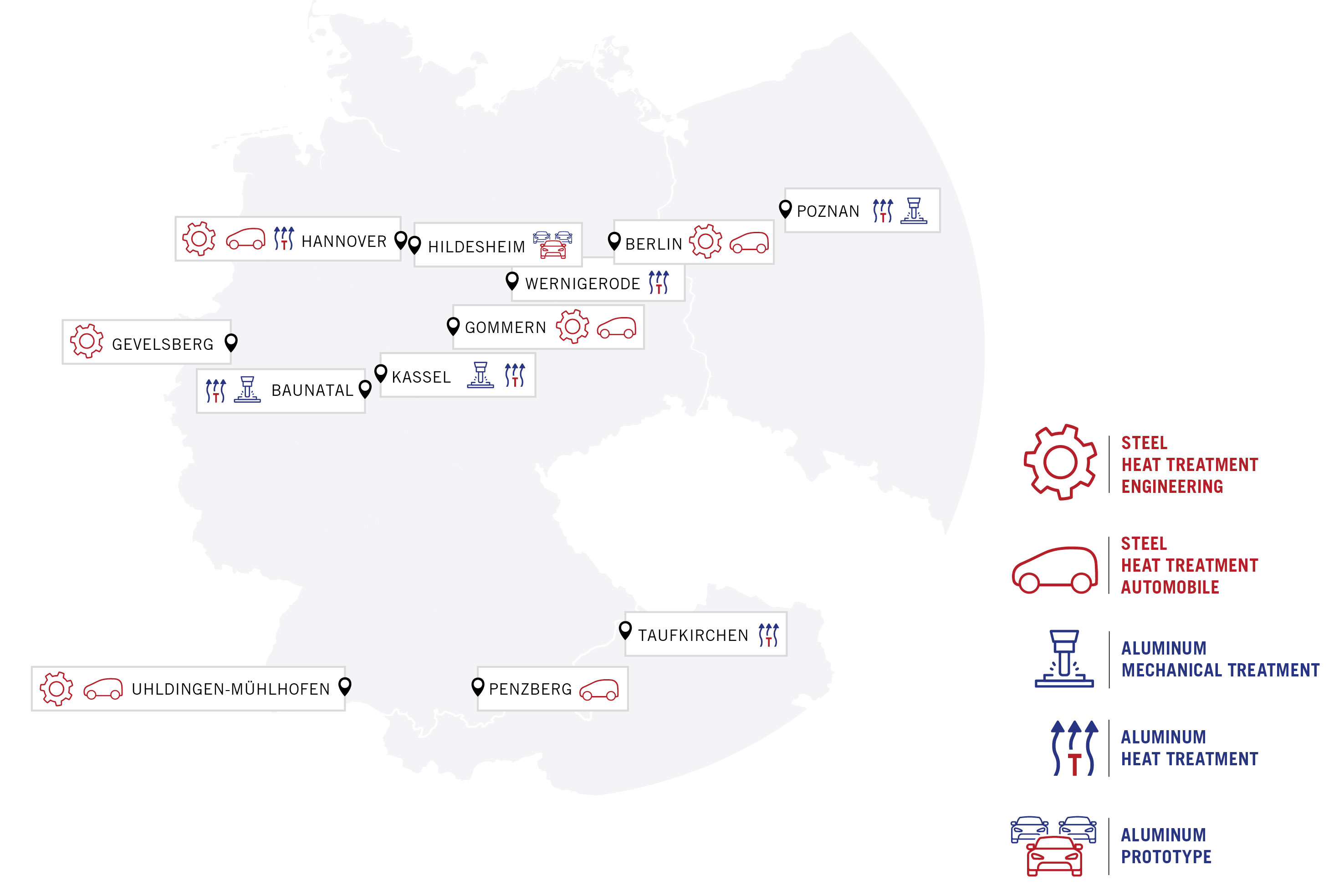

Wir bieten Ihnen an zehn Standorten modernste Anlagentechnik und dank erfahrener Spezialisten bauteilspezifische, ausgereifte Wärmebehandlungskonzepte an. Eine termingenaue Logistik und ein transparenter Informationsaustausch über den gesamten Behandlungsprozess ist für uns eine Selbstverständlichkeit.

Viele Kunden wünschen sich einen verantwortlichen Lieferanten vom Rohteil bis zum geprüften einbaufähigen Fertigbauteil, deshalb haben wir an vielen Standorten auch mechanische Bearbeitungszentren zur Vervollständigung der Prozesskette integriert.

Auf Wunsch beraten wir Sie gerne auch zu Werkstoffthemen und helfen Ihnen, die für Ihre Ansprüche bestmögliche Wärmebehandlung oder den kostenoptimalen Fertigungsprozess für Ihre Bauteile zu finden.

Willkommen bei der Hanomag Lohnhärterei Gruppe!