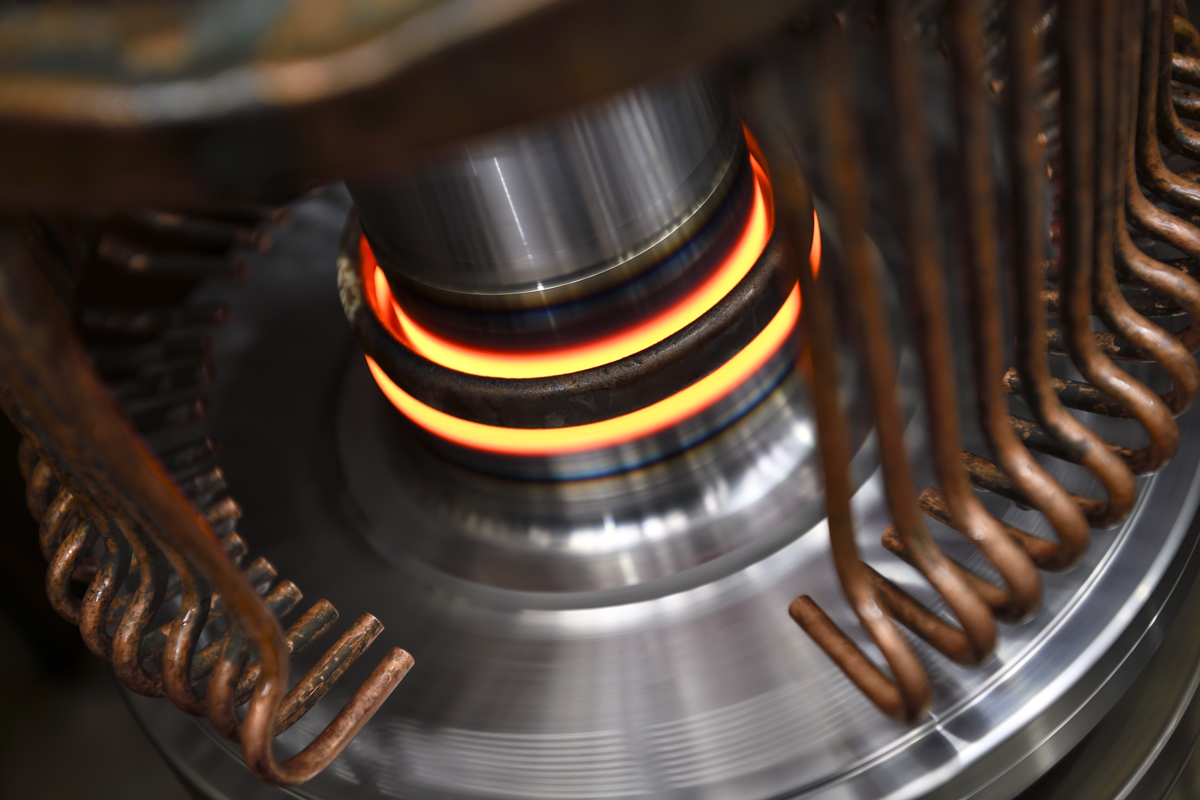

Inductive hardening

Inductive hardening, like flame hardening, is a surface layer hardening process.

However, here the component is heated with electrical alternating voltage, which creates heat by induction in the region near the surface. Here the surface hardening depth is primarily determined by the frequency. There are different CNC - controlled high and medium frequency facilities available in the Hanomag Heat Treatment Group, and their program control enables a high degree of reproducibility - not only for series parts.

Since carbon is primarily the controlling factor for achieving the desired hardness, other higher-alloy and high-alloy materials such as X155CrVMo12 are eligible for inductive hardening besides tempered steels with a carbon content of 0.4 % upwards.

Benefits of inductive hardening

- Partial hardening according to needs

- Short process times

- Relatively slight dimensional and shape changes

- High reproducibility due to CNC control system